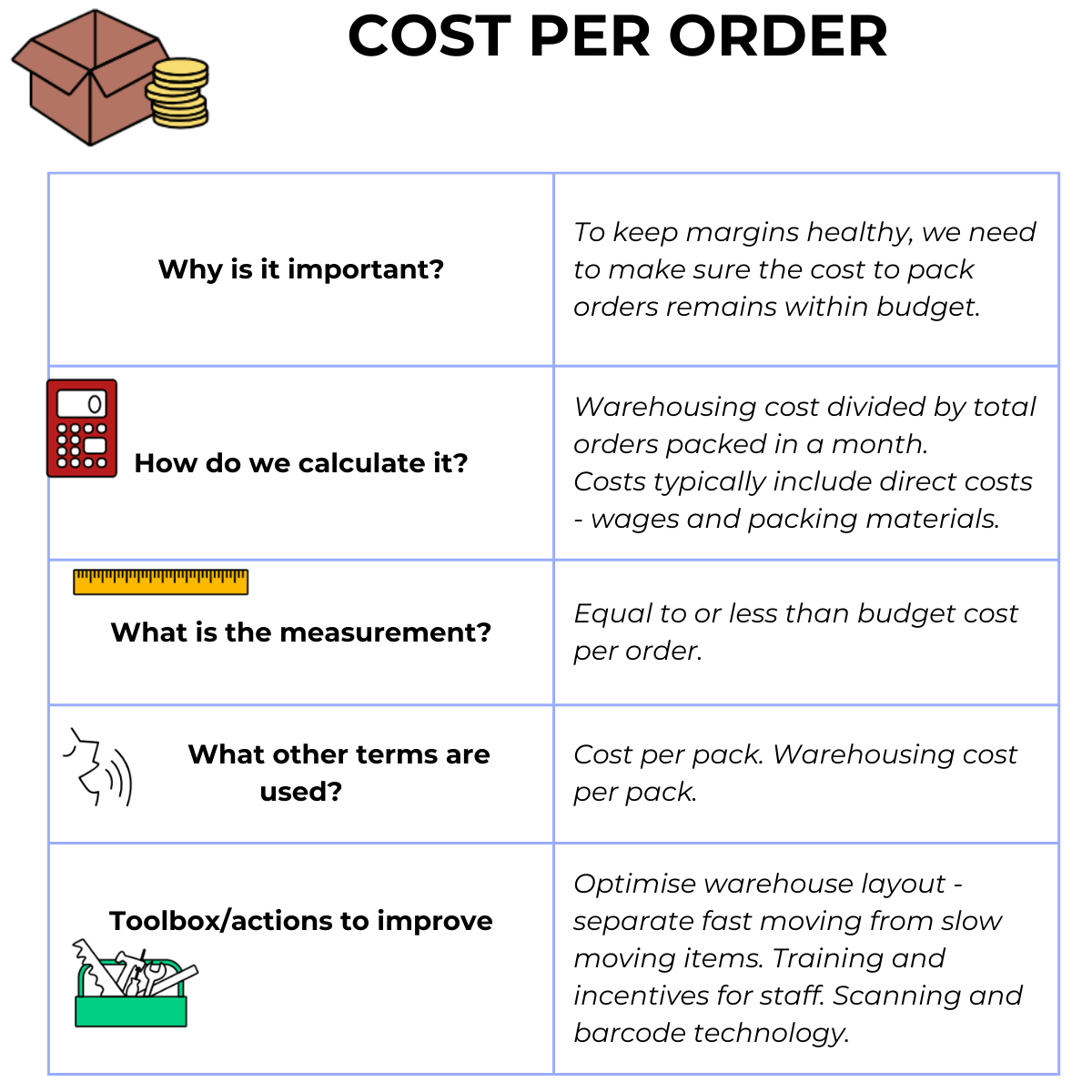

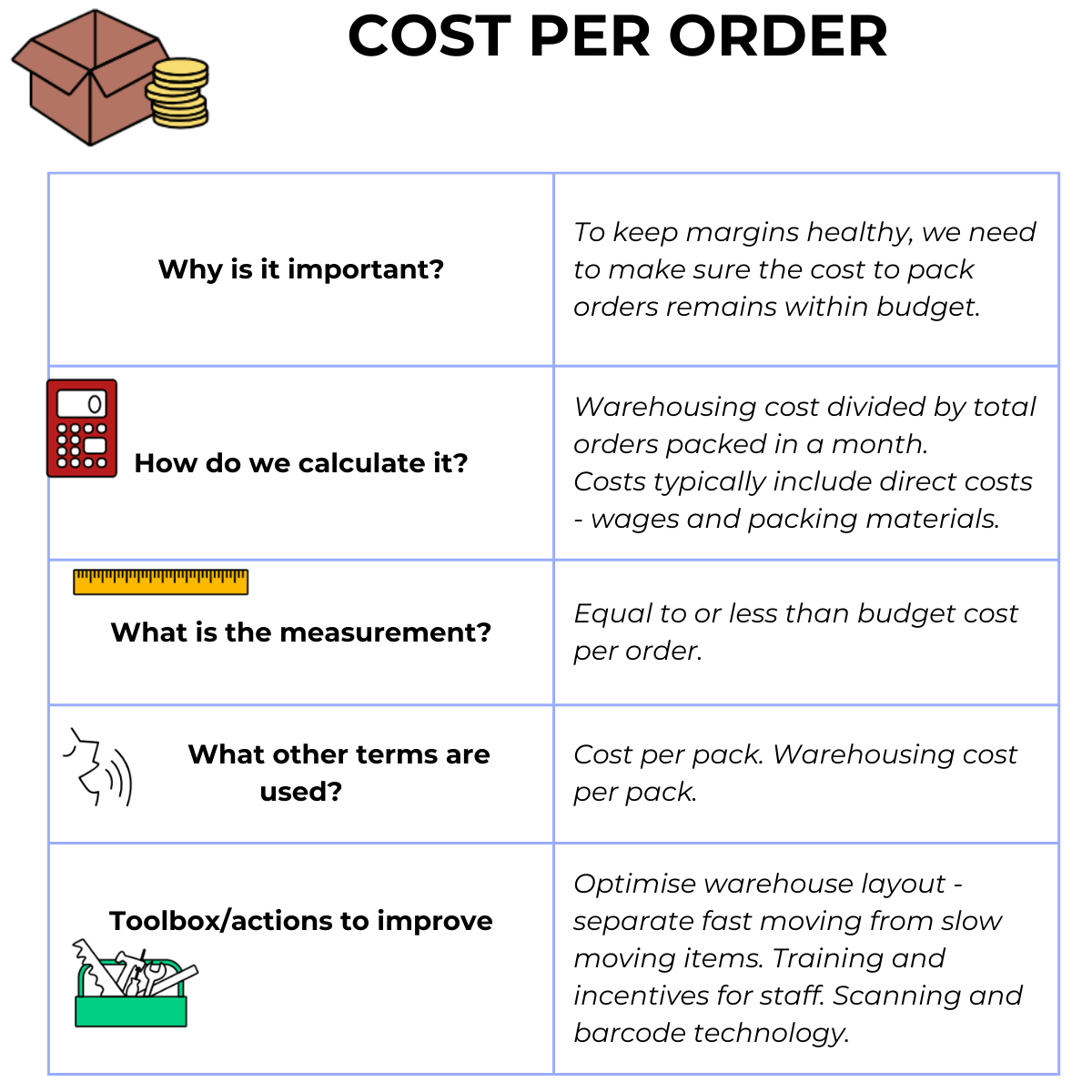

Measuring the cost to pack each order is important to maintain overall margins.

Typically we include variable costs, such as wages and packing materials.

Example:

Wages $100,000

Pension 401K/Superannuation $10,000

Boxes, bubble wrap, tape and consumables $50,000

Total costs $160,000

Orders packed 40,000

Total costs 160,000 / Orders packed 40,000 = $4 per order

Customers expect their orders to be shipped in full and to arrive on time. DIFOT is a standard way of ensuring our warehousing and distribution is meeting customer expectations.

Warehouse layout can be optimised by dividing inventory into A-B-C:

A - Fast-moving / High-demand (Typically 20% of items)

Location: Closest to packing/shipping stations

Goal: Minimize walking/picking time

Storage Tips: Pick face at ground level / waist height

B - Medium moving (Typically 15% of items)

Location: Mid-range

Storage Tips: 1 shelf above A items, close to A

C - Slow moving (Typically 5% of items)

Location: Furthest from shipping station

Storage Tips: High shelves, bulk storage, alternative warehouse

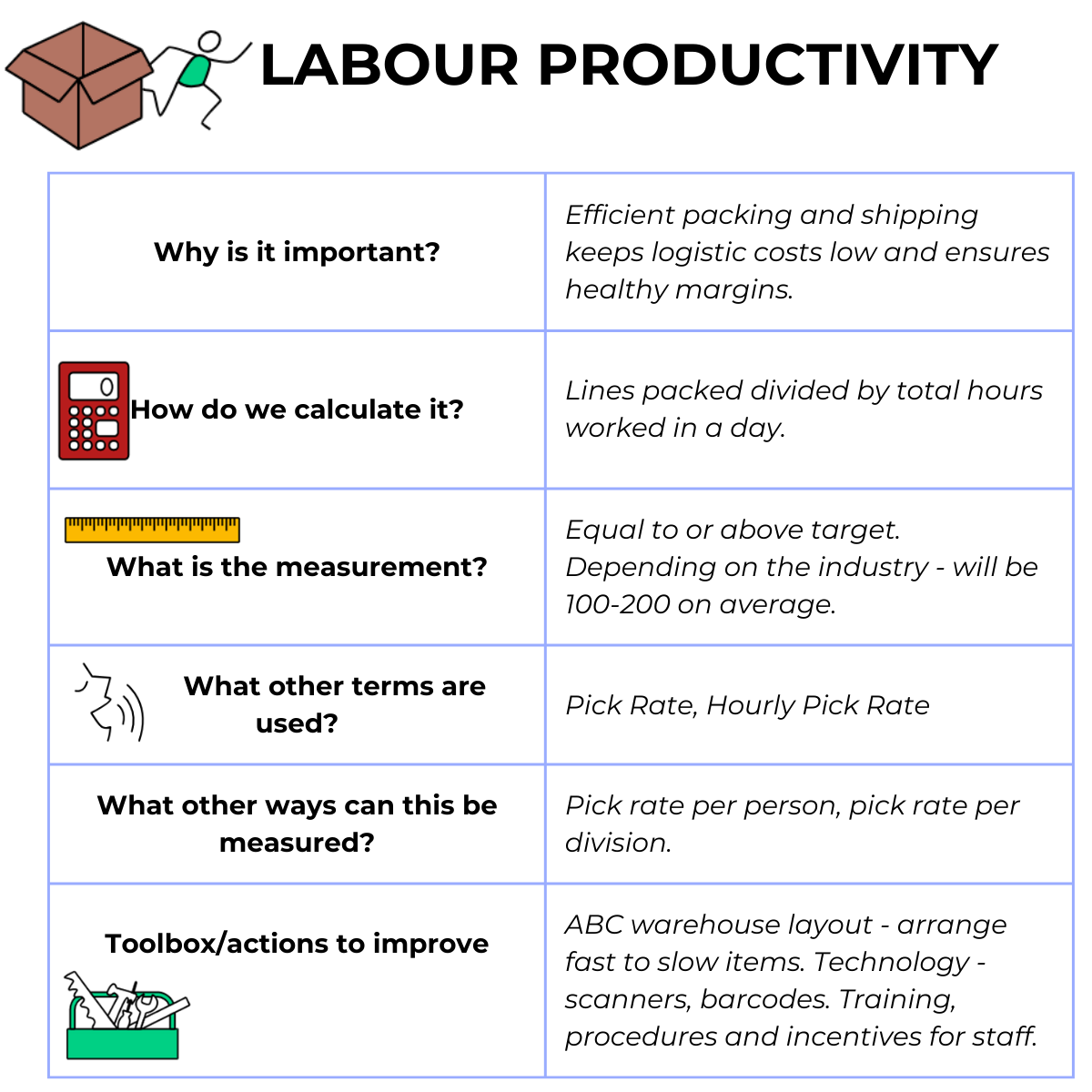

Labour productivity is typically measured using total lines picked divided by hours worked.

Ways to improve:

- Track picks/hour per worker/shift/SKU

- Conduct time and motion studies

- Offer bonuses for high pick rates with low errors

- Use barcode or RFID scanners

- Mobile devices with real-time WMS access

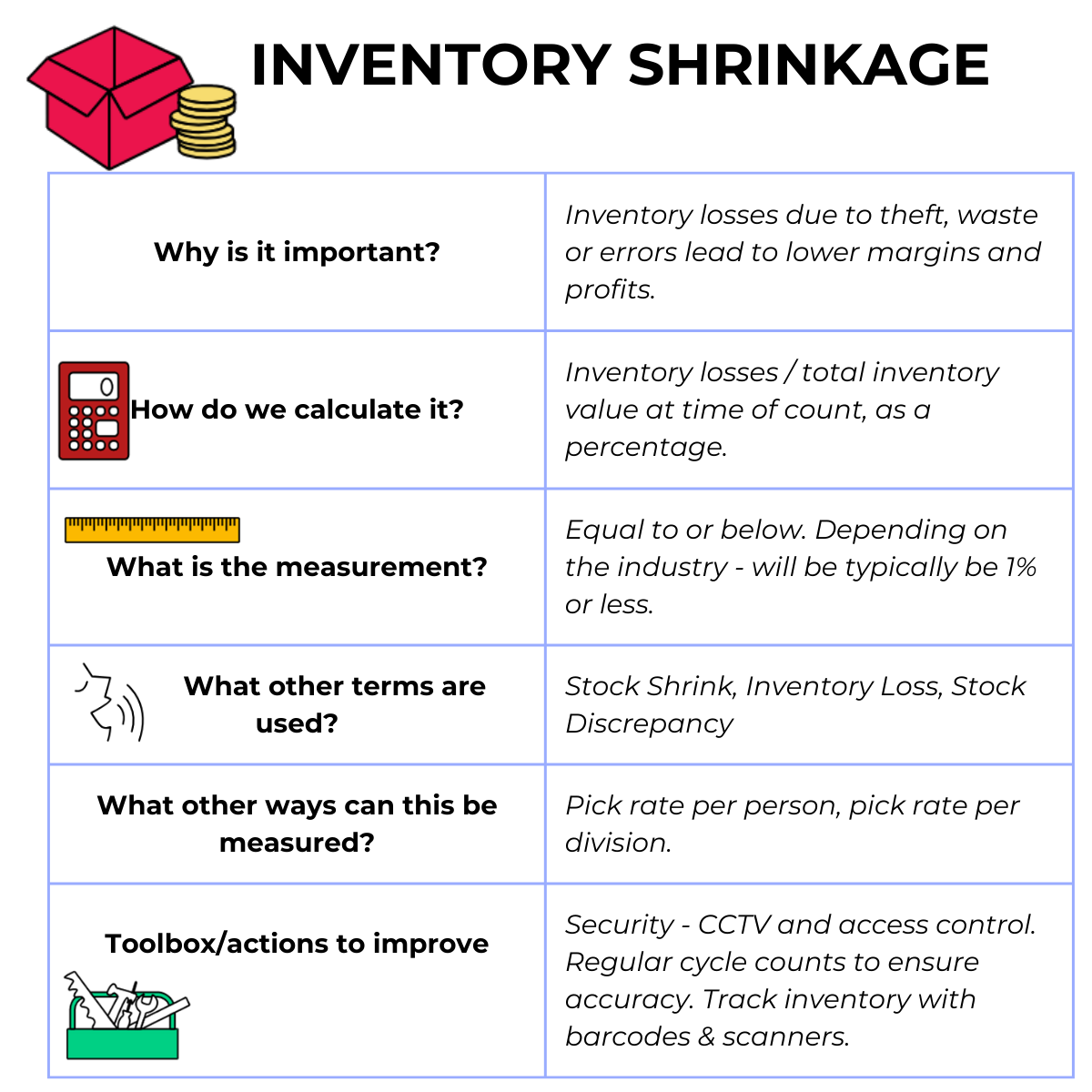

Inventory shrinkage is usually a combination of:

- Errors in inventory receipting

- Inventory count errors

- Inventory dispatch errors

- Waste and damage

- Theft

Ways to improve:

- Cycle counting instead of annual stocktakes

- Barcode/RFID scanning for all movements

- Implement a Warehouse Management System (WMS)

- Track shrinkage by SKU, zone, or shift

- Create a “no blame, just report” culture