A company may have strong marketing but can lose margin and customer loyalty with poor production.

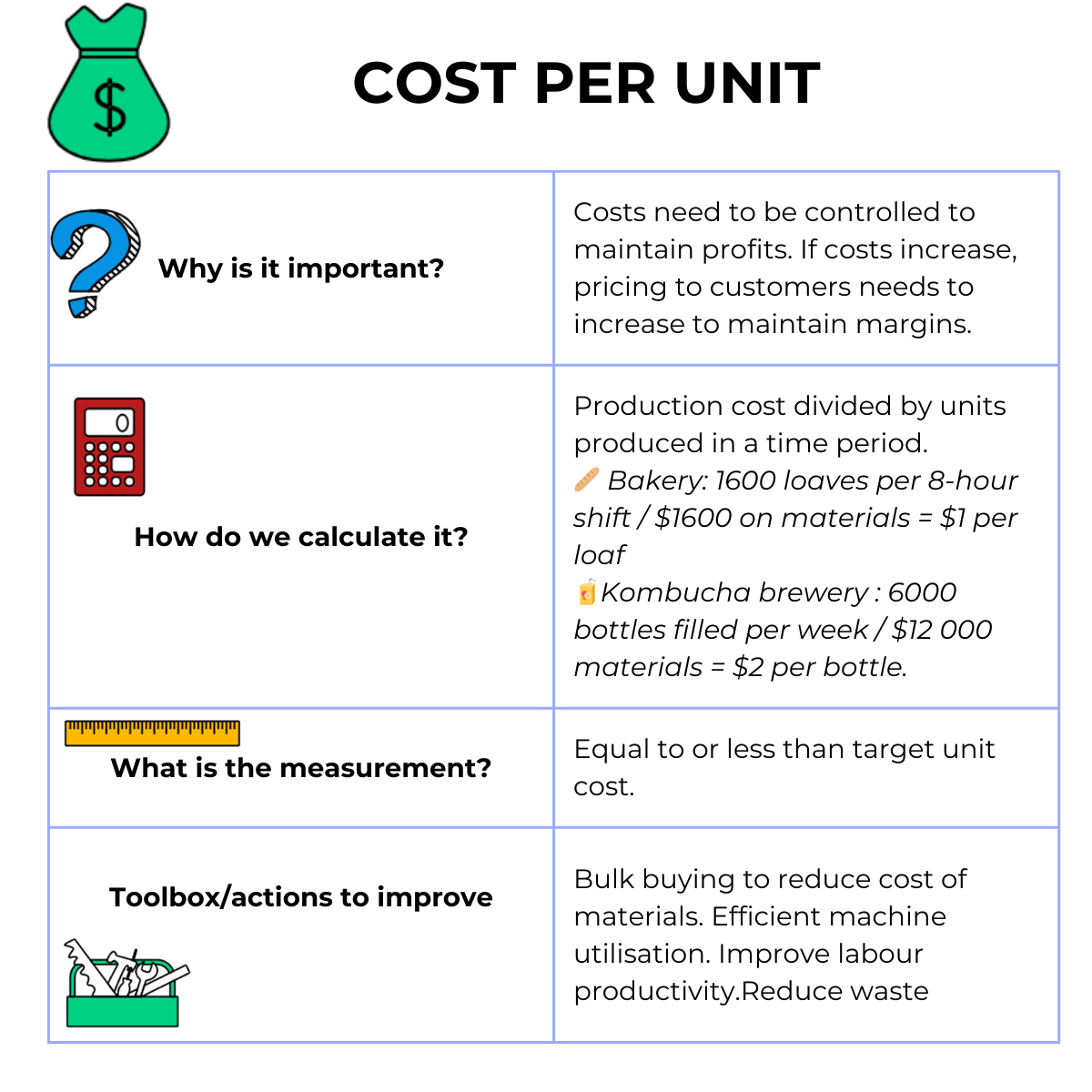

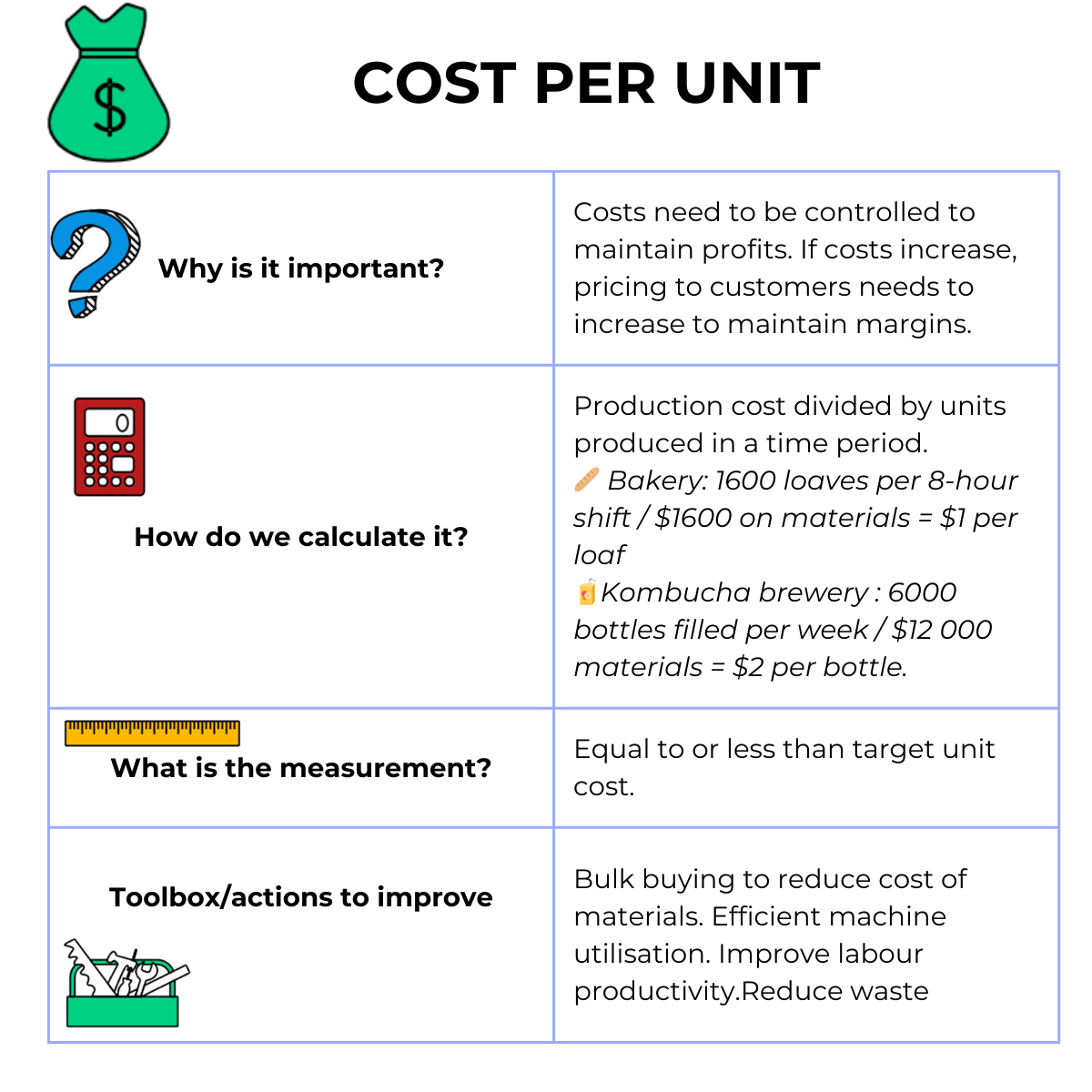

Measuring cost per unit is the starting point of cost control and maintaining profits.

Ways to improve:

💼 Buy raw materials in bulk for better rates.

🧮 Larger production batch sizes: Larger batches spread fixed costs (labor, cleaning) across more units.

👷 Reduce labor hours per batch via more efficient staffing or automation.

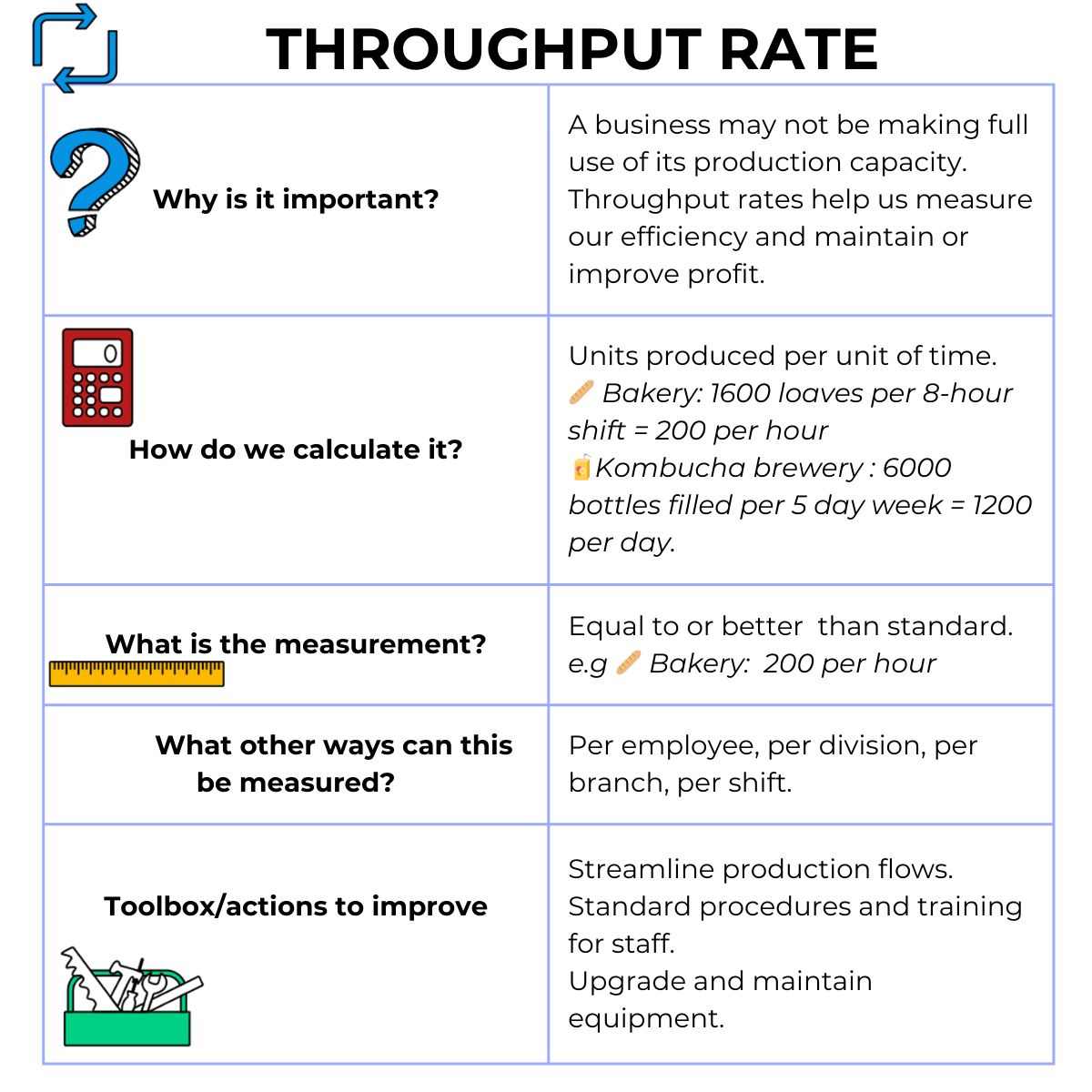

A company may be producing high volumes, but not making full use of its capacity.

Toolbox / actions to improve:

✅ Streamline workflows: properly mapped workflow reduces double handling and improves production

🛠️ Upgrade or maintain equipment: Faster or more reliable machines boost output.

📋 Standardise procedures: Clear SOPs (standard operating procedures) reduce confusion, mishandling and delays.

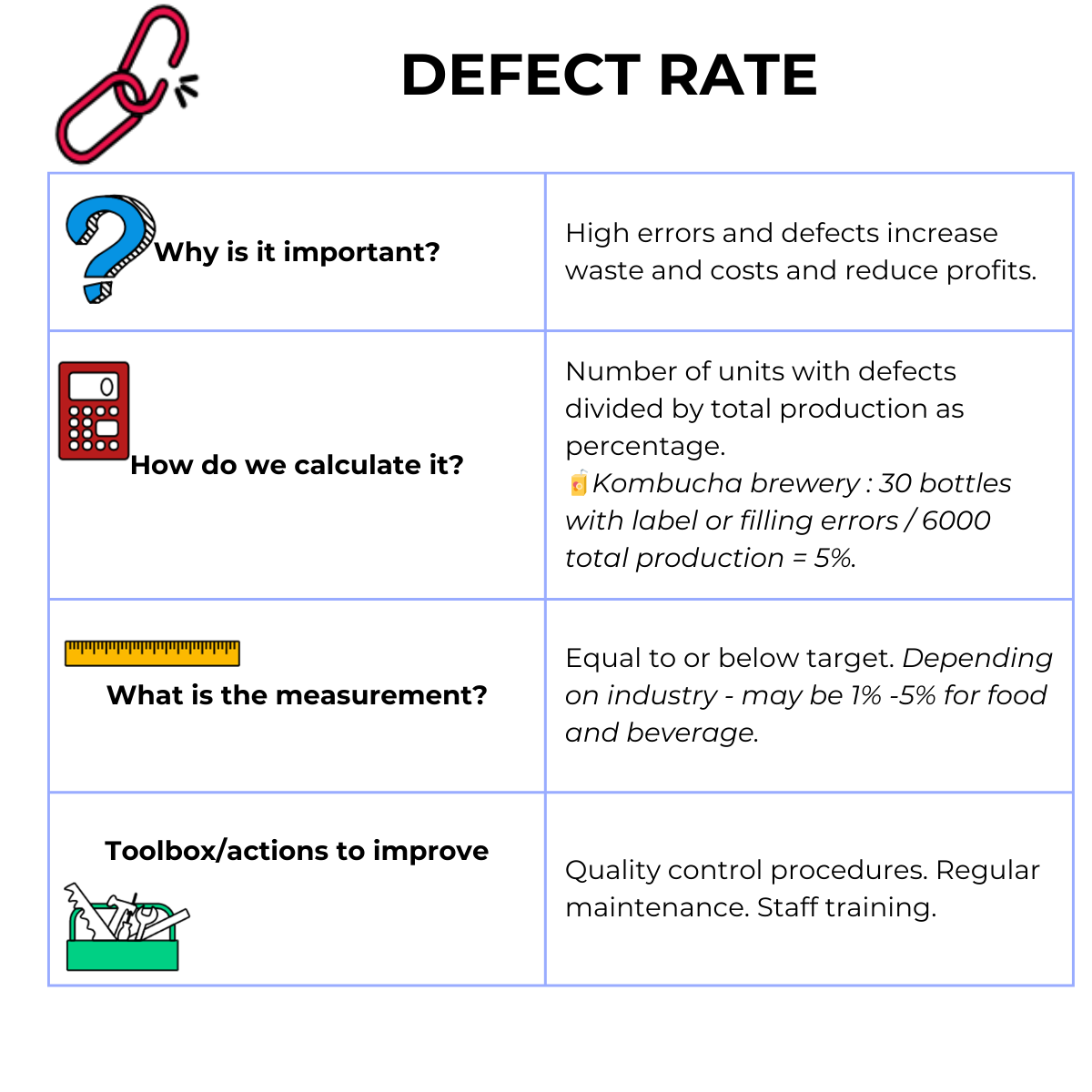

A company may have high production, but a high rate of errors or defects.

Reducing defects = lower costs and higher profit.

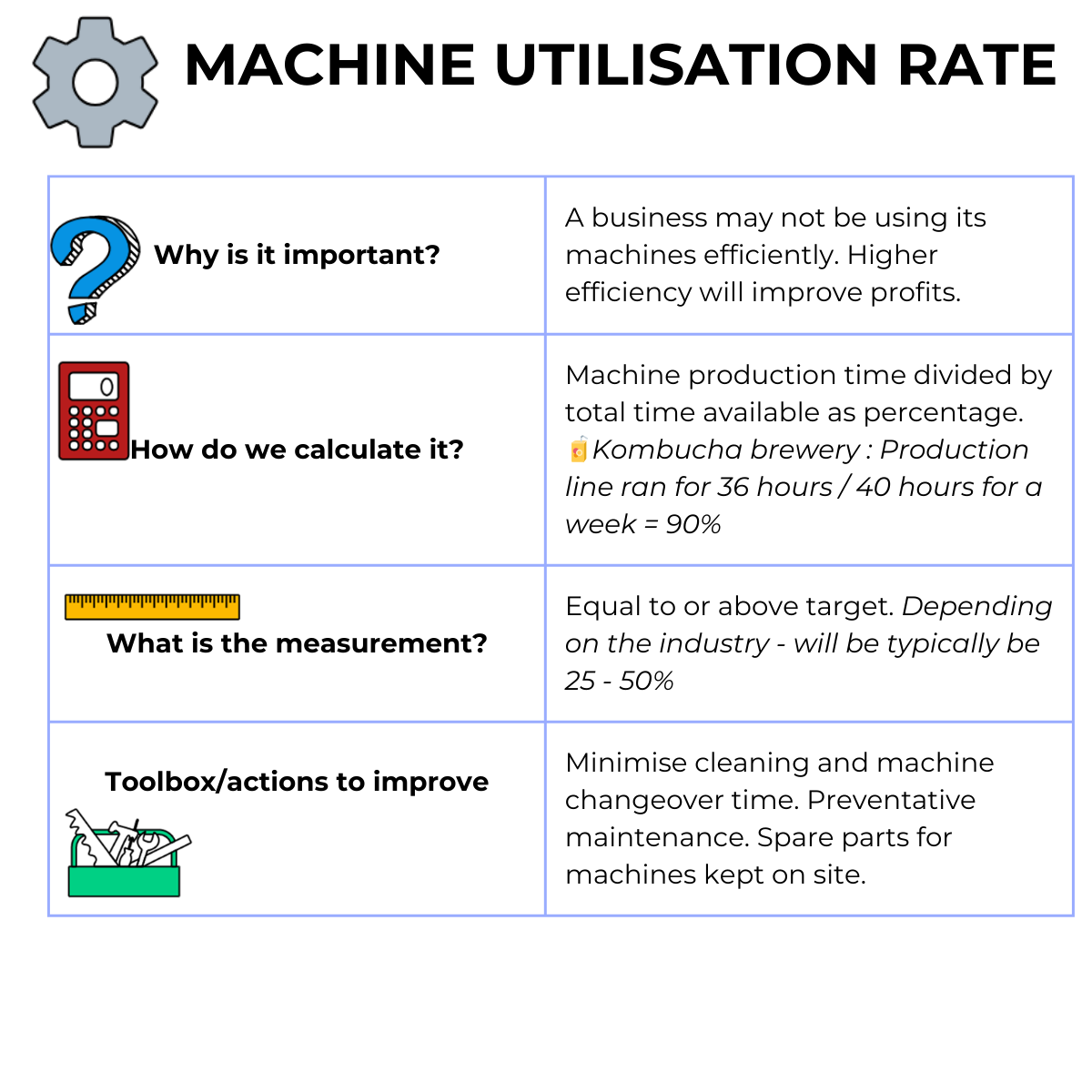

A business may have modern production facilities, but may not be using them at their full potential.

How to Improve:

🧽 Schedule cleaning/maintenance during off-hours or after shifts.

📊 Use production planning software to improve scheduling.

🔧 Keep critical spare parts on-site to reduce downtime for minor repairs.

🕒 Track downtime reasons (e.g., cleaning, setup, waiting on materials) and address them systematically.

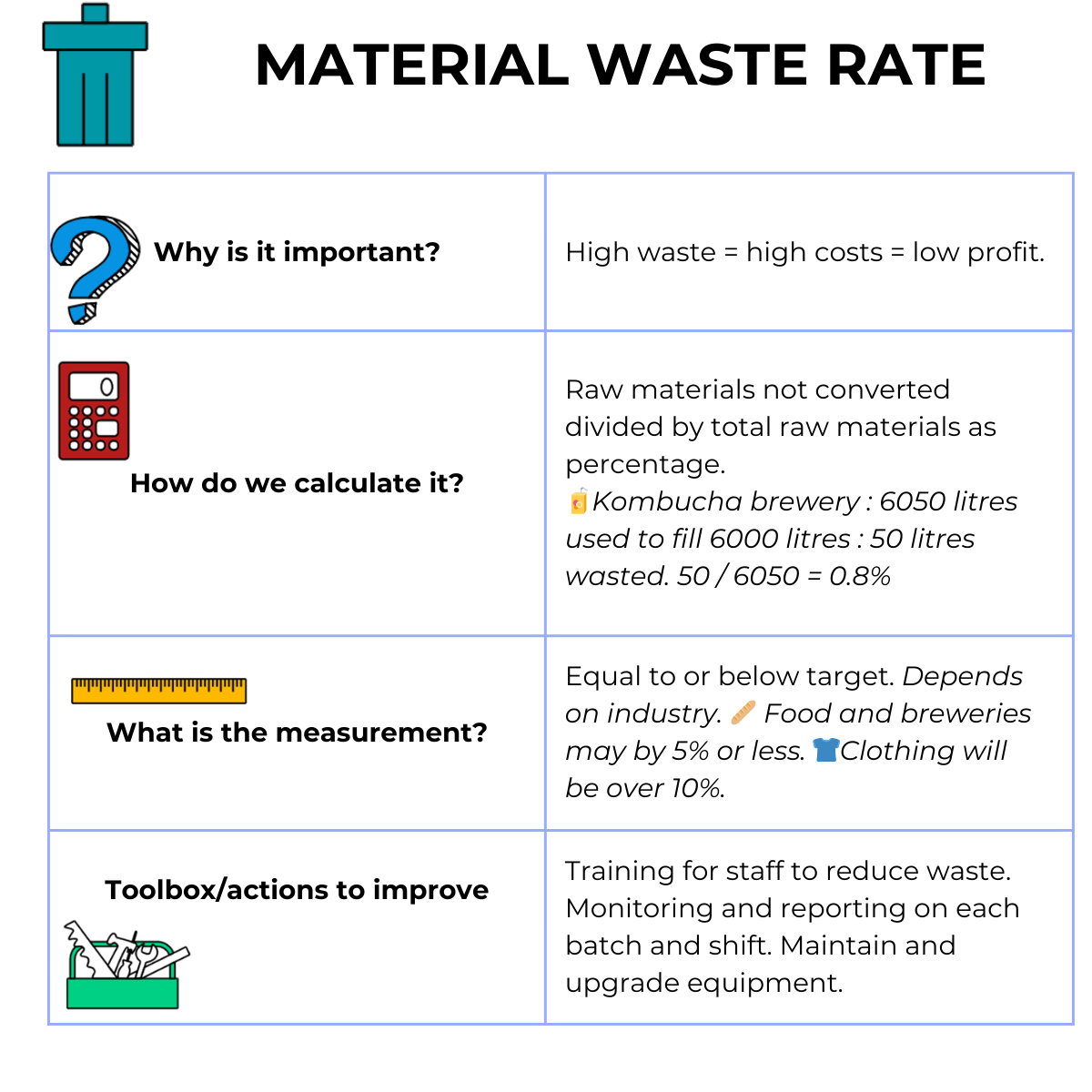

Waste = higher costs = lower profits.

Toolbox to improve:

🧪 Install precision equipment to reduce errors, spillage and waste.

🚫 Identify and prevent processes that create waste.

🧹 Train staff on procedures to avoid loss.

📈 Track waste per batch to identify patterns (e.g., certain staff shifts or products with higher loss).